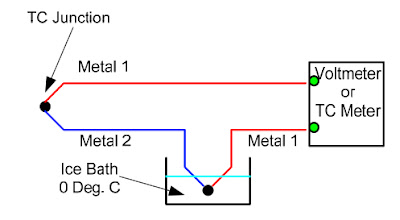

- A thermocouple is a simple temperature measurement device consisting of a junction of two dissimilar metals.

- Contrary to popular belief, the voltage measured (and converted to a temperature) is not a function of the junction alone. Rather it is the temperature difference (or gradient) between the junction (or hot), end and the reference (or cold), end.

- A thermocouple circuit whose junction and reference are the same temperature will measure no temperature (0V).

- If this were not true, we could create a self-sustaining voltage generator using a thermocouple, a resistive load and an oven, that would require energy only at start-up.

The temperature equation for the simplest of thermocouple circuits shown above is:

T = Tjunc – Tref

Where T is the desired measurement, Tjunc is the hot junction temperature and Tref is the reference

temperature, or cold end.

For simplicity’s sake, we use T, Tjunc and Tref here, but in reality these are voltages that are later converted to a temperature.

Cold Junctions

The temperature equation for this diagram is:

T = Tjunc – Tcj1 – Tcj2

A fundamental problem when using thermocouples is the fact the when connected to a measurement device (voltmeter or TC meter), a third metal is introduced (the connecting terminals), and two more thermocouple junctions are created. These adversely affect the temperature being measured. The new, (and unwanted), junctions are referred to as “cold junctions” and need some type of “cold junction compensation” in order to make accurate measurements.

In addition to the added variables in the previous equation, the temperature of the cold junctions

(reference end), is still not known. The following rule helps things out a bit:

- If both TC connections to the meter are of the same metal or alloy, they cancel each other and have no affect on the measurement, as long both connections are at the same temperature (which can be assumed).

Since the definition of a thermocouple states that it must be of dissimilar metals, a second thermocouple must be introduced to the circuit to achieve this. This was the first of what is commonly called “cold junction compensation”

By adding a second series thermocouple suspended in an ice bath, the cold junctions at the meter are of identical metals and cancel each other. In addition, the temperature of the ice bath is known to be 0 Deg. C and becomes the reference end of the thermocouple.

The temperature equation is now simplified and once again becomes:

The temperature equation is now simplified and once again becomes:

T = Tjunc – Tref

While the ice bath reference junction eliminates errors, it is clearly impractical for most, if not all applications. Fortunately, all of today’s thermocouple read back options (meters, chart recorders, PLCs, etc.), come equipped with cold junction compensation, usually a thermistor and associated circuitry and software. By taking the cold junction worries out of the picture, the thermocouple remains one of the simplest, most robust and widely used temperature measurement devices around.