"This is my wish for you: peace of mind, prosperity through the year, happiness that multiplies, health for you and yours, fun around every corner, energy to chase your dreams, joy to fill your holidays!" D.M. Dellinger

A blog providing information about industrial temperature measurement, specifically in the areas of temperature sensors. The posts will contain educational information about thermocouples, RTDs, and other common types of temperature sensors. The application of these sensors will focus on aerospace, aircraft, research and development, medical, chemical, plastics processing, and power generation industries. For more, visit Duro-Sense.com or call 310-533-6877.

Monday, December 23, 2019

Thursday, December 19, 2019

Engine Compressor Thermocouples Provide the Reliability Needed for Offshore Use

Offshore oil and gas platforms require an uninterrupted source of electricity to power a wide variety of specialized equipment used to drill for oil. Pumps, valve operators, critical communications, turntables, motors, and safety systems are just a subset of the drilling and production ecosystem requiring a reliable source of power. Just as critical is the large amounts of electrical power required for the habitation. Electrical generators provide the power for comfort heating, cooling, desalination of water, food preparation, and even waste processing. The power requirements of an offshore platform is not unlike that of a small town.

The most common source of power for these offshore rigs are diesel powered generators. While diesel is still the most common, alternative fuels such as gas, heavy oil, and steam turbines are being produced for offshore platform use. Major turbine manufacturers continue to develop technologies that efficiently use one, or a combination, of these fuels. Additionally, increased savings and efficiencies are being realized through adopting waste heat recovery systems. These recovery systems assist by reusing and recycling energy from exhaust gases of turbines and generators.

Conditions on offshore platforms are harsh. Equipment and components must provide stable

Conditions on offshore platforms are harsh. Equipment and components must provide stable operation and, by design, reduce the need for frequent maintenance and overhaul. A specialized temperature sensor, referred to as an "engine compressor thermocouple" is used on platform generator turbines. These are specially designed, heavy-duty temperature sensors used for measuring the exhaust gases from engines, turbines and compressors. These sensors are time-tested and built to withstand the harsh mechanical and environmental conditions subjected by offshore, marine conditions.

For more information about offshore platform compressor thermocouples contact Duro-Sense. You can reach them by phone by calling 310-533-6877 or visit their web site at https://duro-sense.com.

Monday, November 25, 2019

Precision Thermocouples and RTDs for the Most Demanding Applications

Duro-Sense Corporation provides the highest quality thermocouples and RTDs to the aerospace, aviation, offshore drilling, medical, R&D, power generation, alternative energy, process control, primary metals, high-tech and OEM industries.

Contact Duro-Sense by calling 310-533-6877 or visit their web site at https://duro-sense.com.

Sunday, November 10, 2019

Duro-Sense Remembers and Thanks Those Who Serve and Protect Our Country

Veterans Day is a day of observance and celebration for those who have served in the United States military. Veterans Day was originally called Armistice Day because of the November 11 Armistice that ended World War I. In 1954 it was officially changed to Veterans Day to include Veterans of all wars. This holiday honors those who took an oath to defend the United States and our Constitution, from all enemies, foreign and domestic. Through the observance of Veterans Day, we remind ourselves of our Veterans patriotism, love of country and willingness to serve and sacrifice for the common good. Duro-Sense thanks our Veterans, past and present, for serving our country and protecting our freedom.

Monday, September 23, 2019

Three Simple Questions for Choosing Thermocouples or RTDs

What's the best choice for your industrial temperature sensing requirement, a thermocouple or RTD? In industrial installations, both types of sensor can be specified with similar mounting accessories, dimensional specifications, and instrument interfaces. However, there are three criteria you need to consider before choosing between an RTD or thermocouple probe.

First, what is the temperature range you are trying to monitor?

Generally, if the temperature exceeds five hundred degrees Celsius (500 deg C), thermocouples are for you. RTD's are best between -200 and 500 °C, while thermocouples have a range of -180 to 2,320 °C. For anything above 500 Celsius, you should select the appropriate thermocouple calibration for the sensing range you're working in.Second, what type of sensor accuracy do you need?

RTDs are more accurate temperature sensors, offer highly repeatable readings, drift less over time, and are suitable for high precision requirements. Thermocouples are generally less accurate and are subject to drift. Typical thermocouple accuracy is 2 deg. C.Third, how about the budget you're working under?

Thermocouples can be up to three times less expensive than RTD probes, making thermocouples a good choice if high accuracy and repeatability are not critical. One caveat though. Make sure you consider any additional cost incurred with long runs of thermocouple extension wire. For installations requiring dozens or even hundreds of temperature sensors, the significant difference in basic sensor cost is an important consideration.These three criteria are VERY basic, and intended just to point you in the right direction. There are many other differences between thermocouples and RTDs that need to be understood before application. Consult a temperature sensor expert prior to installing or specifying a thermocouple or RTD wherever or whenever failure can cause harm.

Wednesday, August 21, 2019

What Kind of Thermocouple Should I Use?

What kind of thermocouple should I use? Depends on several variables related to the system to be tracked, such as its media / process environment compatibility, the frequency and precision of the necessary measurements, and the regulatory climate in your sector.

What kind of thermocouple should I use? Depends on several variables related to the system to be tracked, such as its media / process environment compatibility, the frequency and precision of the necessary measurements, and the regulatory climate in your sector.Temperature measurement in many industries, from refining to pharmaceuticals to aerospace, is a key parameter in manufacturing and processing operations. Precise temperature monitoring helps to ensure safe, efficient and optimal results.

A thermocouple is invariably the measuring tool of choice for applications above 1400° F, but the selection of the ideal industrial thermocouple also requires knowledge of the process where the device will be used.

INTERFACE WITH PROCESS

First, consider whether the thermocouple is itself in direct contact with the process media or whether it is incorporated into a thermocouple assembly that includes a thermowell. Thermowells are metal, glass, or ceramic tubes that protect the thermocouple against corrosive, fast-flowing or highly hot process media. About 75% of heavy industry thermocouples use thermowell assemblies; these industries include refining, petrochemical, the pulp and paper industry, and power generation.JUNCTION

The thermocouple junction design depends on the applications requirements for response speed and the likelihood of electrical noise being conducted through the process. A thermocouple has three variations of sensing tip (or junction): Exposed junction, where the exposed wire tips and welded bead have no covering or protection; Grounded junction, where the welded bead is in physical contact with the thermocouple's sheath; Ungrounded junction, where the tip is inside the thermocouple sheath, but is electrical (and somewhat thermally) insulated from the sheath (no sheath contact).MATERIAL SELECTION

Material selection is the second criteria to choose. A vast majority of industrial thermocouples are made from stainless steel, but specialized alloys such as Inconel 600, Hastelloy X, Monel, and other unique metals are required in certain applications.MOUNTING

Next, you have to consider the mounting arrangement. You need to determine whether a more traditional industrial thermocouple/well/head design is required, or if some sort of flexible or remote thermocouple sensor is required for use in a hard to access area.TYPE

Last, you have to decide the "type" of industrial thermocouple you need. In the case of thermocouples, "type" refers to the composition of metal wires in the instrument whose physical properties respond to changes in temperature. Different metal compositions have different temperature ranges and other properties that make them suitable for use in special applications, or inappropriate for use.- Type J thermocouples use iron for the positive leg and copper-nickel (constantin) alloys for the negative leg. They may be used unprotected where there is an oxygen-deficient atmosphere, but a thermowell is recommended for cleanliness and generally longer life. Because the iron (positive leg) wire oxidizes rapidly at temperatures over 1000 deg.F, manufacturers recommend using larger gauge wires to extend the life of the thermocouple when temperatures approach the maximum operating temperature.

- Type K thermocouples use chromium-nickel alloys for the positive leg and copper alloys for the negative leg. They are reliable and relatively accurate over a wide temperature range. It is a good practice to protect Type K thermocouples with a suitable ceramic tube, especially in reducing atmospheres. In oxidizing atmospheres, such as electric arc furnaces, tube protection may not be necessary as long as other conditions are suitable; however, manufacturers still recommend protection for cleanliness and prevention of mechanical damage. Type K thermocouples generally outlast Type J, because the iron wire in a Type J thermocouple oxidizes rapidly at higher temperatures.

- Type N thermocouples use nickel alloys for both the positive and negative legs to achieve operation at higher temperatures, especially where sulfur compounds are present. They provide better resistance to oxidation, leading to longer service life overall.

- Type T thermocouples use copper for the positive leg and copper-nickel alloys for the negative leg. They can be used in either oxidizing or reducing atmospheres, but, again, manufacturers recommend the use of thermowells. These are good stable thermocouples for lower temperatures.

- Types S, R, and B thermocouples use noble metals for the leg wires and are able to perform at higher temperatures than the common Types J and K. They are, however, easily contaminated, and reducing atmospheres are particularly detrimental to their accuracy. Manufacturers of such thermocouples recommend gas-tight ceramic tubes, secondary porcelain protective tubes, and a silicon carbide or metal outer protective tube depending on service locations.

For more information about industrial thermocouples, contact Duro-Sense Corporation. Call them at 310-533-6877 or visit their web site at https://duro-sense.com.

Friday, July 26, 2019

Duro-Sense Corporation: Celebrating Our 40th Year in Business

Duro-Sense designs and manufactures temperature sensors and assemblies used in power generation, plastics production, semiconductor processing, environmental control, packaging, aerospace, medical equipment, foodservice equipment and a myriad of other industries. Duro-Sense partners with customers to optimize their temperature sensing processes, thereby assisting in improving their customers efficiency and profitability.

Since 1979, Duro-Sense has grown exponentially in product capability and market experience. The company today continues to succeed by operating under a simple core value – providing customers with superior products, meticulously engineered for their individual requirements.

Since 1979, Duro-Sense has grown exponentially in product capability and market experience. The company today continues to succeed by operating under a simple core value – providing customers with superior products, meticulously engineered for their individual requirements.

Thursday, July 11, 2019

Duro-Sense: A Long History of Solving Tough Temperature Sensing Problems

With engineering, design, and support resources available at their headquarters in Southern California, Duro-Sense delivers value-added temperature sensing solutions that improve operations and increase profitability for customers in the power generation, alternative energy, plastics, medical, gas & oil, chemical, refining, mining, agricultural, food service, pharmaceutical, and aerospace industries.

With engineering, design, and support resources available at their headquarters in Southern California, Duro-Sense delivers value-added temperature sensing solutions that improve operations and increase profitability for customers in the power generation, alternative energy, plastics, medical, gas & oil, chemical, refining, mining, agricultural, food service, pharmaceutical, and aerospace industries.Duro-Sense offers their customers products and services designed to provide outstanding value and cost savings throughout the customer's equipment life span. By integrating the highest quality standards, state-of-the-art machinery, and decades of application experience, Duro-Sense assists customers through:

- Improved product quality

- Optimize asset uptime and performance

- Lower total cost of operation and maintenance

- Increase equipment reliability

- Improve plant and personnel safety

ENGINEERING AND TECHNICAL SERVICES

Technical Analysis — Duro-Sense can identify temperature sensor operational issues that may be constraining output or elevating operating costs, and then recommend laser-focused solutions.

Reliability and Efficiency Services — Duro-Sense lends their decades of hands-on experience to offer practical temperature sensing solutions that improve the performance, efficiency, and reliability of your process control equipment - all while lowering your total cost of ownership.

Loop Design, Integration and Engineering Support — Duro-Sense engineers engage with their customers, providing support for grassroots project planning, system design, or project management requirements.

Equipment Life Cycle Optimization — Through a combination of assessments and technology, Duro-Sense experts help customers benchmark operational performance, define key metrics, and implement precise sensor solutions to achieve long-term operational goals.

Intelligent Product Design — By employing an array of sophisticated products, services, and software that collects, examines and understands data, Duro-Sense helps customers use predictive analytics to take action and improve asset reliability and reduce downtime.

Have a challenging temperature sensing requirement? Call Duro-Sense.

Duro-Sense Corporation

310-533-6877

Monday, July 1, 2019

Sunday, June 30, 2019

US Power Grids, Oil and Gas Industries, and Risk of Hacking

A report released in June, from the security firm Dragos, describes a worrisome development by a hacker group named, “Xenotime” and at least two dangerous oil and gas intrusions and ongoing reconnaissance on United States power grids.

Multiple ICS (Industrial Control Sectors) sectors now face the XENOTIME threat; this means individual verticals – such as oil and gas, manufacturing, or electric – cannot ignore threats to other ICS entities because they are not specifically targeted.

The Dragos researchers have termed this threat proliferation as the world’s most dangerous cyberthreat since an event in 2017 where Xenotime had caused a serious operational outage at a crucial site in the Middle East.

The fact that concerns cybersecurity experts the most is that this hacking attack was a malware that chose to target the facility safety processes (SIS – safety instrumentation system).

For example, when temperatures in a reactor increase to an unsafe level, an SIS will automatically start a cooling process or immediately close a valve to prevent a safety accident. The SIS safety stems are both hardware and software that combine to protect facilities from life threatening accidents.

At this point, no one is sure who is behind Xenotime. Russia has been connected to one of the critical infrastructure attacks in the Ukraine. That attack was viewed to be the first hacker related power grid outage.

This is a “Cause for Concern” post that was published by Dragos on June 14, 2019.

“While none of the electric utility targeting events has resulted in a known, successful intrusion into victim organizations to date, the persistent attempts, and expansion in scope is cause for definite concern. XENOTIME has successfully compromised several oil and gas environments which demonstrates its ability to do so in other verticals. Specifically, XENOTIME remains one of only four threats (along with ELECTRUM, Sandworm, and the entities responsible for Stuxnet) to execute a deliberate disruptive or destructive attack.

XENOTIME is the only known entity to specifically target safety instrumented systems (SIS) for disruptive or destructive purposes. Electric utility environments are significantly different from oil and gas operations in several aspects, but electric operations still have safety and protection equipment that could be targeted with similar tradecraft. XENOTIME expressing consistent, direct interest in electric utility operations is a cause for deep concern given this adversary’s willingness to compromise process safety – and thus integrity – to fulfill its mission.

XENOTIME’s expansion to another industry vertical is emblematic of an increasingly hostile industrial threat landscape. Most observed XENOTIME activity focuses on initial information gathering and access operations necessary for follow-on ICS intrusion operations. As seen in long-running state-sponsored intrusions into US, UK, and other electric infrastructure, entities are increasingly interested in the fundamentals of ICS operations and displaying all the hallmarks associated with information and access acquisition necessary to conduct future attacks. While Dragos sees no evidence at this time indicating that XENOTIME (or any other activity group, such as ELECTRUM or ALLANITE) is capable of executing a prolonged disruptive or destructive event on electric utility operations, observed activity strongly signals adversary interest in meeting the prerequisites for doing so.”

Thermocouple Extension Wire

Thermocouple extension wire is a single pair wire that cannot be made into a thermocouple, but is used to carry the signal from a thermocouple to the recorder, controller, or instrument reading the signal.

Extension grade wire is used to carry a signal representing the higher temperature seen by the sensing location, but extension wire itself cannot be generally exposed to those higher temperatures.

Extension wire cannot be used to make a thermocouple, but thermocouple wire can be used as extension wire. Insulation is typically PVC, but other option are available.

Multi-pair extension wire is simply more than a single pair in the same jacket. It is extension onlyand is usually available in 2, 4, 6, 8, 12, 16, and 24 pairs. It is used primarily when a contractor has to run multiple runs of wire. It allows them to run one piece of wire rather than multiple individual runs.

Multi-pair extension wire is simply more than a single pair in the same jacket. It is extension onlyand is usually available in 2, 4, 6, 8, 12, 16, and 24 pairs. It is used primarily when a contractor has to run multiple runs of wire. It allows them to run one piece of wire rather than multiple individual runs.

For more information on all varieties of thermocouple wire, contact Duro-Sense by calling 310-533-6877 or visiting https://duro-sense.com.

Extension grade wire is used to carry a signal representing the higher temperature seen by the sensing location, but extension wire itself cannot be generally exposed to those higher temperatures.

Extension wire cannot be used to make a thermocouple, but thermocouple wire can be used as extension wire. Insulation is typically PVC, but other option are available.

Multi-pair extension wire is simply more than a single pair in the same jacket. It is extension onlyand is usually available in 2, 4, 6, 8, 12, 16, and 24 pairs. It is used primarily when a contractor has to run multiple runs of wire. It allows them to run one piece of wire rather than multiple individual runs.

Multi-pair extension wire is simply more than a single pair in the same jacket. It is extension onlyand is usually available in 2, 4, 6, 8, 12, 16, and 24 pairs. It is used primarily when a contractor has to run multiple runs of wire. It allows them to run one piece of wire rather than multiple individual runs.For more information on all varieties of thermocouple wire, contact Duro-Sense by calling 310-533-6877 or visiting https://duro-sense.com.

Monday, May 27, 2019

Friday, May 24, 2019

Quick Comparison of Temperature Sensors

Thermocouples are commonly used because of their simplicity, reliability, and relative low cost. They are self-powered and eliminate the need for a separate sensor power supply. Thermocouples are quite durable when selected for a given application appropriately. Thermocouples can also be used for applications with high temperatures.

Resistance temperature detectors (RTDs) are attractive alternatives to thermocouples when the output is desired to be highly accurate, stable and linear (i.e. just how close the calibration curve looks a straight line). The superior linearity of relative temperature resistance enables simpler signal processing devices for RTDs than thermocouples.

Thermistors are similar to RTD because they're a resistance measurement device, but thermistors use a very cheap polymer or ceramic material as the element in lieu of the use of pure metal.

For more information on any type of industrial or OEM temperature sensor, contact Duro-Sense by calling 310-533-6877 or by visiting https://duro-sense.com.

Labels:

industrial thermocouple,

OEM,

RTD,

temperature sensor,

thermistor,

thermocouple

Wednesday, April 24, 2019

Friday, April 19, 2019

Thermocouples: Proper Use, Recommended Practices, and Avoiding Problems

|

Proper use and maintenance of thermocouple systems begin with good system design based on the strengths and weaknesses of various thermocouple types. Because these sensors contain sensitive electronics, general good practice includes use of shielded cases and twisted- pair wire, use of proper sheathing, avoidance of steep temperature gradients, use of large-gauge extension wire, and use of guarded integrating voltmeters or ohmmeters, which electronically filter out unwanted signals. The signal conditioner should be located as close as possible to the sensor, and twisted copper-wire pairs should be used to transmit the signal to the control station. To minimize electromagnetic field interference, sensor system wires should not be located parallel to power supply cables. The primary causes of loss of calibration in thermocouples include the following:

- Electric “noise” from nearby motors, electric furnaces, or other such electrically noisy equipment;

- Radio frequency interference from the use of hand-held radios near the instrument.

- “Ground loops” that result when condensation and corrosion ground the thermocouple and create a ground loop circuit with another ground connection in the sensing circuit.

Most problems with thermocouples are aggravated by use of the thermocouple to measure temperatures that approach or exceed their upper temperature limits. Careful recording of events that could affect measurements should be kept in a logbook. Any adjustments or calibrations should also be recorded. The logbook should contain the names of individuals performing maintenance and calibrations as well as defined procedures. In systems monitoring many locations, such a log is especially useful for fault diagnosis.

Thermocouples sometimes experience catastrophic failures, which may be preceded by extreme oscillations or erratic readings. In such cases, all connections associated with the thermocouple should be checked for loose screws, oxidation, and galvanic corrosion. In many cases, drift may be a more serious problem because it can go unnoticed for long periods of time. The most common causes of loss of calibration are excessive heat, work hardening, and contamination. Work hardening generally is due to excessive bending or vibration and can be prevented with properly designed thermowells, insertion lengths, and materials. Contamination is caused by chemicals and moisture, which sometimes attack wiring by penetrating sheaths, and can result in short-circuiting. A simple test to check for this problem is to disconnect the sensor at its closest connection and check for electrical continuity between the wires and the sheath using a multimeter. If the meter indicates continuity, the sensor should be replaced. Because the electromotive force (EMF) produced by thermocouples is so small, electrical noise can severely affect thermocouple performance. For that reason, it also is very important that transmitters be isolated. Thermocouples used in the vicinity of electrostatic precipitators must be shielded to avoid electrical interference. If the potential electrical interference is high, an RTD or other type of sensor may be preferred to thermocouples. With respect to thermocouple and protection tube selection, the following should be noted:

- Type J thermocouples particularly should not be used in applications in which they might be exposed to moisture because the iron in the thermocouple will rust and deteriorate quickly;

- Type K thermocouples should not be used in the presence of sulfur, which causes the element to corrode; because cutting oils often contain sulfur, protection tubes should be degreased before being used; stainless steel sheaths should be used to protect Type K thermocouples in stacks where SO2 emissions are significant;

- Platinum thermocouple elements (Types R, S, or B) should not be used with metal protection tubes unless the tubes have a ceramic lining because the metal will contaminate the platinum;

- Ceramic, silicon carbide, and composite (metal ceramic, Cerite-II, Cerite-III) protection tubes are subject to thermal shock and should be preheated prior to inserting in high temperature process environments; and

- Molybdenum - or tantalum-sheathed thermocouples will fail rapidly if placed in oxidizing atmospheres.

During one study of thermocouple performance, 24 combinations of thermocouple and sheath material types were tested at temperatures up to 1200 C (2200 F). The results indicated that above 600 C (1110 F) thermocouples are affected by complex chemical interactions between their components; even though wires and sheaths were physically separated, exchange of constituents occurred. The study concluded that thermocouples maintain calibration better if sheath material is similar in composition to thermocouple alloys. By using similar alloys longer performance can be expected for sensors subjected to temperatures above 600 C (1110 F), and the use of similar alloys is essential for temperatures above 1000 C (1830 F).

For more information on the proper use of thermocouples, contact Duro-Sense Corporation by calling (310) 533-6877 or visit their website at https://duro-sense.com.

Reprinted from CAM Technical Guidance Document courtesy of EPA.gov.

Sunday, March 31, 2019

Digital Food Thermometers: Thermocouples

|

| Specialized thermocouple, with handle and sharpened point, used in food preparation. |

A thermocouple measures temperature at the junction of two fine wires located in the tip of the probe. Thermocouples used in scientific laboratories have very thin probes, similar to hypodermic needles, while others may have a thickness of 1/16 of an inch.

Since thermocouple thermometers respond so rapidly, the temperature can be quickly checked in a number of locations to ensure that the food is safely cooked. This is especially useful for cooking large foods, such as roasts or turkeys, when checking the temperature in more than one place is advised. The thin probe of the thermocouple also enables it to accurately read the temperature of thin foods such as hamburger patties, pork chops, and chicken breasts.

Thermocouples are not designed to remain in the food while it's cooking. They should be used near the end of the estimated cooking time to check for final cooking temperatures. To prevent overcooking, check the temperature before the food is expected to finish cooking.

Thermocouples can be calibrated for accuracy.

For more information of food industry thermocouples, contact Duro-Sense Corporation by calling 310-533-6877 or visiting https://duro-sense.com.

Monday, March 25, 2019

A Pro and Con Comparison of Thermocouples and RTDs

Thermocouple Advantages

- Inexpensive

- Wide temperature range

- Various types, sizes and application methods

- Remote read back

- Read back electronics can be simple

- Usable in virtually any environment

- Requires cold junction compensation

- Slow response time

- Not as accurate as many other devices without good CJC and calibration

- Susceptible to noise

- Connection cable/wire is expensive compared to copper conductors

- Cable/wire length is limited

- More linear than thermocouples

- Cold junction not an issue

- Special cable/wire not needed

- Cable/wire length can be much longer than TC’s

- Better noise immunity

- More stable over time than thermocouples

- Remote read back

- Usable in virtually any environment

- More expensive than thermocouples

- More delicate than thermocouples unless encased

- Not as wide of temperature range as thermocouples

- Requires more conductors per device

- Read back electronics more complex

Tuesday, March 12, 2019

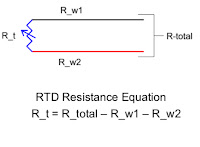

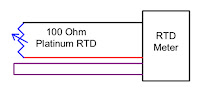

Theory of RTD Operation

An RTD is a temperature measuring device that changes resistance with temperature change, rather than changing voltage, as with a thermocouple.

An RTD is a temperature measuring device that changes resistance with temperature change, rather than changing voltage, as with a thermocouple.Most commonly used is the platinum 100 ohm RTD because of their stability in air and linearity. Their resistance is 100 ohms @ 0 Deg.C and increases with temperature.

Common terms associated with RTD’s are temperature coefficient or alpha, and tolerance class.

Common terms associated with RTD’s are temperature coefficient or alpha, and tolerance class.Alpha is ohms per ohm per Deg.C.

The average resistance change per unit of temperature from boiling point to ice point of water:

- Rboiling – Rice point/100deg/100ohms

- 138.5 – 100.0/100/100 = .00385

Tolerance class is the amount an RTD will differ from the standard resistance curve per Deg.C.

- Class A (+/- .15 + .002*t)

- @ temp of 100DegC = +/- .35DegC

When ordering an RTD, a tolerance class will be part of the order, dependent on the application. IEC 751 stipulates that the RTD be marked with their nominal R0 value, their tolerance class, the wiring configuration and the temperature range.

|

| 3-wire configuration |

- Pt100 / A / 3 / -100/+200 = Platinum 100 Ohm / Class A / 3-Wire / -100 to +200 Deg.C

|

| 2-wire configuration |

Another configuration is a two wire RTD with a stand-alone loop. (Probably rarely used today).

Since the RTD is a resistance device, the resistance of the wires used to connect the RTD to the measurement meter introduces errors and must be known. This is the reason a third (or fourth), wire is used.

|

| 3rd wire used to cancel wire error |

Then the meter reads the resistance of one of the common wires, the RTD, and the non-common wire to determine Rtotal

|

| Meter reading 2 common wires |

Rt = Rtotal – Rwire

Thursday, February 28, 2019

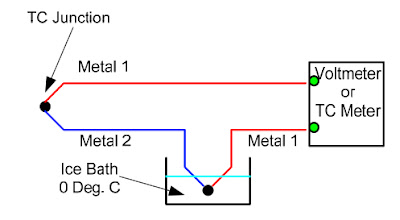

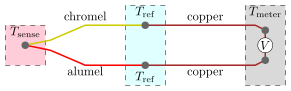

Theory of Thermocouple Operation

- A thermocouple is a simple temperature measurement device consisting of a junction of two dissimilar metals.

- Contrary to popular belief, the voltage measured (and converted to a temperature) is not a function of the junction alone. Rather it is the temperature difference (or gradient) between the junction (or hot), end and the reference (or cold), end.

- A thermocouple circuit whose junction and reference are the same temperature will measure no temperature (0V).

- If this were not true, we could create a self-sustaining voltage generator using a thermocouple, a resistive load and an oven, that would require energy only at start-up.

The temperature equation for the simplest of thermocouple circuits shown above is:

T = Tjunc – Tref

Where T is the desired measurement, Tjunc is the hot junction temperature and Tref is the reference

temperature, or cold end.

For simplicity’s sake, we use T, Tjunc and Tref here, but in reality these are voltages that are later converted to a temperature.

Cold Junctions

The temperature equation for this diagram is:

T = Tjunc – Tcj1 – Tcj2

A fundamental problem when using thermocouples is the fact the when connected to a measurement device (voltmeter or TC meter), a third metal is introduced (the connecting terminals), and two more thermocouple junctions are created. These adversely affect the temperature being measured. The new, (and unwanted), junctions are referred to as “cold junctions” and need some type of “cold junction compensation” in order to make accurate measurements.

In addition to the added variables in the previous equation, the temperature of the cold junctions

(reference end), is still not known. The following rule helps things out a bit:

- If both TC connections to the meter are of the same metal or alloy, they cancel each other and have no affect on the measurement, as long both connections are at the same temperature (which can be assumed).

Since the definition of a thermocouple states that it must be of dissimilar metals, a second thermocouple must be introduced to the circuit to achieve this. This was the first of what is commonly called “cold junction compensation”

By adding a second series thermocouple suspended in an ice bath, the cold junctions at the meter are of identical metals and cancel each other. In addition, the temperature of the ice bath is known to be 0 Deg. C and becomes the reference end of the thermocouple.

The temperature equation is now simplified and once again becomes:

The temperature equation is now simplified and once again becomes:

T = Tjunc – Tref

While the ice bath reference junction eliminates errors, it is clearly impractical for most, if not all applications. Fortunately, all of today’s thermocouple read back options (meters, chart recorders, PLCs, etc.), come equipped with cold junction compensation, usually a thermistor and associated circuitry and software. By taking the cold junction worries out of the picture, the thermocouple remains one of the simplest, most robust and widely used temperature measurement devices around.Monday, February 25, 2019

Thermocouple Wire Insulation Materials

|

Nylon

- Suggested operating range: -85°F to 250°F (-65°C to 121°C)

- Nylon provides high tensile, impact and flexural resistance. It has excellent resistance to abrasion and is unaffected by most alkalis, oil, grease, dilute mineral acids and most organic acids. It is inert to most organic solvents including hydraulic fluid and aviation oil. The individual conductors and outer jacket are extruded.

- Suggested operating range: -90°F to 400°F (-67°C to 204°C)

- FEP retains useful strength and flexibility over broad ranges of environmental temperature or thermal aging. FEP is flame retardant and non-propagating in fire conditions. It is moisture and chemical resistant and accepted for use around food and pharmaceuticals. The individual conductors and outer jacket are extruded.

- Suggested operating range: -328°F to 500°F (-200°C to 260°C)

- Flame retardant PFA provides flexibility and toughness with stress crack resistance, resistance to weather, non-aging characteristics and a low coefficient of friction. PFA also provides outstanding electrical characteristics, as well as resistance to virtually all chemicals. The individual conductors and outer jacket are extruded.

- Suggested operating range: -328°F to 500°F (-200°C to 260°C)

- TFE is flame retardant (passes IEEE 383 & VW-1 flame tests) and has excellent solvent and abrasion resistance. TFE is unaffected by long term exposure to virtually all chemicals and solder iron temperatures. The individual conductors and outer jacket are insulated with TFE Tape.

- Suggested operating range: -400°F to 600°F (-240°C to 315°C)

- Kapton is extremely tough. It has excellent abrasion, impact and cut through resistance, very high resistance to oxidative degradation, weathering, and all chemicals except strong bases. Kapton also offers high dielectric strength and insulation resistance. Kapton does not support combustion; even at extremely high temperatures, it decomposes slowly without visible burning. It is also resistant to radiation. The individual conductors and outer jacket are insulated with Kapton Tape.

- Suggested maximum operating temperature: 900°F (482°C) continuous 1000°F (538°C) single exposure {Impregnation maintained to 400°F (200°C)}

- Fiberglass insulation, with the special binder impregnation, offers good moisture and chemical resistance, as well as good abrasion resistance. Typical applications include aerospace, foundries, heat treating, plastics industry and a wide variety of other uses.

- Hi-Temp Fiberglass - Suggested maximum operating temperature: 1300°F (704°C) continuous, 1600°F (871°C) single exposure {Impregnation maintained to 400°F (200°C)}

For more information about thermocouple wire insulation materials contact Duro-Sense Corporation by calling 310-533-6877 or visiting https://duro-sense.com.

Friday, February 15, 2019

Temperature Sensing IS Rocket Science

Duro-Sense Corporation provides the precision temperature sensors to the aerospace, aviation, and space industries. Duro-Sense engineers bring proven solutions to your most difficult problems. Their R&D department is staffed with some of the industry's most qualified people, working in the most modern facilities to help advance the state of the art in temperature measurement.

Thursday, January 31, 2019

Thermocouples

|

| Diagram of a thermocouple circuit. |

|

| Typical sheathed thermocouple. |

Because of their wide range of models and technical specifications, it is extremely important to understand their basic structure, functionality and range in order to better determine the right thermocouple type and material for an application.

Operating Principle

When two wires consisting of different metals are connected at both ends and one end is heated, a continuous current flows through the thermoelectric circuit. If this circuit is broken in the center, the net open circuit voltage (Seebeck Effect) depends on the temperature of the junction and the composition of the two metals. This means that a voltage is produced when the connection of the two metals is heated or cooled that can be correlated to the temperature.

Contact Duro-Sense Corporation with any questions about applying industrial and commercial thermocouples.

Duro-Sense Corporation

https://duro-sense.com

310-533-6877

Monday, January 28, 2019

Where to Mount Industrial Temperature Transmitters?

In an industrial plant, where there are normally long distances between the measuring points and the receiving instrumentation, some important aspects regarding the location of the transmitters can be mentioned.

In an industrial plant, where there are normally long distances between the measuring points and the receiving instrumentation, some important aspects regarding the location of the transmitters can be mentioned.There are basically three different locations for the mounting of the temperature transmitters:

- In-head mounting - inside the connection head of the temperature sensors.

- Field mounting – close to the temperature sensors.

- Central mounting - in the vicinity of the control room

In-head mounting

The transmitters are mounted directly inside the connection head and are normally replacing the terminal block. This way of mounting normally offers the biggest advantages. It is however necessary to be aware of the environmental influence (mainly the temperature) on the measurement accuracy.Advantages

- Maximum safety in the signal transmission. The amplified signal, e.g. 4- 20 mA, is very insensitive to electrical disturbances being induced along the transmission cable.

- Cost savings for the transmission cables. Only two leads are required if a 2- wire transmitter is used.

- Cost savings for installation. No extra connection points because of the transmitter.

- Cost and space savings. No extra housings or cubicles are needed.

- Field instruments, e.g. indicators, can easily be installed, also at a later stage without redesigning the measuring circuits.

- The ambient temperatures can be out- side the allowed limits for the transmitters.

- The ambient temperature influence on the measuring accuracy has to be considered.

- Extreme vibrations might cause malfunction of the transmitters.

- The location of the temperature sensor can give maintenance problems.

Field mounting

The transmitters are either mounted directly beside the temperature sensors or in the vicinity of the sensors. Often more than one transmitter is mounted in the same field box.This method is more expensive than In-head mounting, but otherwise a good alternative offering most of the advantages of In-head mounting without the disadvantages mentioned above.

Advantages

- High safety in the signal transmission. The main part of the signal transmission is made with an amplified signal.

- No extreme temperatures or vibrations exist. This facilitates accurate and safe measurements.

- Cost savings for transmission cables.

- A wider selection of transmitters is available. DIN rail transmitters can also be used.Field instruments can often be installed easily.

- Maintenance can normally be carried out without problems.

- Higher installation costs compared to In-head mounting.

- Costs and space requirements for transmitter boxes or cubicles.

Central mounting

In this case, the transmitters are placed in the vicinity of the control room or in another central part of the plant They are often mounted inside cubicles, and/or closed rooms. The ambient conditions are normally very good and stable.This method offers the most convenient conditions for maintenance and the best possible environment for the transmitters. There are on the other hand some disadvantages that should be considered.

Advantages

- Convenient conditions for installation, commissioning and maintenance.

- Minimum risk for environmental influences (e.g. temperature influence).

- Reduced safety in the signal transmission. The low-level sensor signal is rather sensitive to electrical disturbances being induced along the trans- mission cable.

- Relatively high costs for cabling. T/C measurements require compensation or extension cables all the way to the transmitters. RTD measurements with high accuracy should be done in 4-wire connection to get rid of the lead resistance influence.

- Costs and space requirements for cubicles or frames.

- Rather complicated and expensive to connect field instruments, e.g. indicators.

For more information on using temperature transmitters, contact Duro-Sense by calling 310-533-6877 or by visiting https://duro-sense.com.

Wednesday, January 16, 2019

Subscribe to:

Posts (Atom)