A blog providing information about industrial temperature measurement, specifically in the areas of temperature sensors. The posts will contain educational information about thermocouples, RTDs, and other common types of temperature sensors. The application of these sensors will focus on aerospace, aircraft, research and development, medical, chemical, plastics processing, and power generation industries. For more, visit Duro-Sense.com or call 310-533-6877.

Sunday, December 30, 2018

Wednesday, December 12, 2018

Happy Holidays from Duro-Sense!

From all of us at Duro-Sense, we wish our customers, partners and vendors a safe and happy holiday season and a wonderful 2019!

Monday, December 10, 2018

Duro-Sense a Critical Partner in Hydrogen Contamination Detector

We take for granted the gasoline (or diesel) we put in our cars and trucks is free from contaminants when pumped in to our gas tanks. The purity we've come to expect at the fuel pump didn't happen overnight. It took many years, and thousands of engineering hours, to develop the refining processes that produces today's clean gasoline and diesel.

Fuel Cell Vehicles are a category of electric vehicle (EV's). Fuel cell vehicles use hydrogen gas (H2) to power an electric motor. Unlike conventional vehicles which run on gasoline or diesel, fuel cell cars and trucks combine hydrogen and oxygen to produce electricity to drive the motor.

Similar to the path that gasoline and diesel processing took toward purity, the use of H2 as feedstock for fuel cells in transportation has driven requirements for H2 purity standards to very strict levels. This push has also elevated the need for cost-effective and reliable instruments that can sample H2 near the nozzle of a delivery pump, and either certify acceptability or provide a signal to shut off the fuel distribution system.

Duro-Sense Corporation, a California based manufacturer of high quality temperature sensors, is part of a team working under a DOE funded research program to develop a Hydrogen Contamination Detector. The sensor, which will be installed at hydrogen fueling stations, will detect poor quality hydrogen gas before entering the fuel cell vehicle. The sensor is intended to detect multiple impurities at extremely low levels in hydrogen to prevent fuel cell performance degradation.

Duro-Sense is designated as the industrial partner and vendor aiding in defining the commercial manufacturability of the Hydrogen Contamination Detector.

As part of their preliminary work, a thermocouple embodiment was selected as a cost-effective platform for the Hydrogen Contamination Detector because:

- Direct Commercial Availability

- Proven History of Reliability and Robustness

- Adaptability of Conductor Materials for Most

- Appropriate Catalyst for Each Contaminant

- Ability to Incorporate up to 12 Conductors a Single Thermocouple, Reducing Fluid Stream Penetrations

The Hydrogen Contamination Detector project is still in its very early stages, and research and development continues, subject to funding and continued interest in alternative fuel technology.

For more information, contact Duro-Sense at 310-533-6877 of visit their web site at https://duro-sense.com.

Tuesday, December 4, 2018

3 Bottom Line Criteria to Help You Choose Between Thermocouples and RTDs

Both RTD and thermocouple probes monitor temperature but which one is right for your application?

The first question to ask yourself is what is the temperature range you are trying to monitor?

Generally, if the temperature is above a hundred and fifty degrees Celsius, a thermocouple would be used. For anything below a hundred and fifty degrees Celsius, an RTD would be used.

The next question to ask is what is the required sensor accuracy?

RTDs provide more accurate readings with repeatable results, this is why RTDs are typically used when temperatures are within its monitoring range.

The last question is what is the purchase budget and how many do you need?

Thermocouples can be up to three times less expensive than RTD probes making thermocouples a good choice when purchasing a large quantity or when the budget is tight

These three criteria are VERY basic, and intended just to point you in the right direction. There are many other differences between thermocouples and RTDs that need to be understood before application. Always consult a temperature sensor application expert prior to installing or specifying a thermocouple or RTD where failure can cause harm.

Duro-Sense Corporation

https://duro-sense.com

The first question to ask yourself is what is the temperature range you are trying to monitor?

Generally, if the temperature is above a hundred and fifty degrees Celsius, a thermocouple would be used. For anything below a hundred and fifty degrees Celsius, an RTD would be used.

The next question to ask is what is the required sensor accuracy?

RTDs provide more accurate readings with repeatable results, this is why RTDs are typically used when temperatures are within its monitoring range.

The last question is what is the purchase budget and how many do you need?

Thermocouples can be up to three times less expensive than RTD probes making thermocouples a good choice when purchasing a large quantity or when the budget is tight

These three criteria are VERY basic, and intended just to point you in the right direction. There are many other differences between thermocouples and RTDs that need to be understood before application. Always consult a temperature sensor application expert prior to installing or specifying a thermocouple or RTD where failure can cause harm.

Duro-Sense Corporation

https://duro-sense.com

(310) 533-6877

Wednesday, November 28, 2018

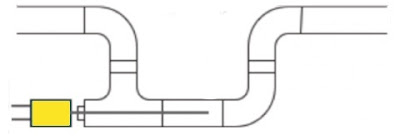

Best Practice for Mounting Thermocouples in Pipes

|

| Diagram 1 - Not recommended. |

There are however, recommended practices for placing thermocouples in the piping flow stream.

As you can see from diagram 1, placing the thermocouple in a tee, positioned perpendicular to flow is not recommended. This is because the conduction along the sensing area may be non-negligible and could bias the measurement, depending on the liquid and ambient temperatures. In addition it may be hard to know precisely where the measurement junction is located along the cross section of the pipe in this configuration.

Ideally they should be mounted in a tee where an elbow would normally be used as you see in diagram 2. If possible the thermocouple should be oriented along the normal flow direction, and the measurement located downstream of the T-bend (the T will help mix the liquid if it is not thermally uniform).

|

| Diagram 2 - Recommended orientation. |

|

| Diagram 3 - Use U shape if there is no convenient placement for a tee. |

For more information, contact Duro-Sense by calling 310-533-6877 or visit their web site at https://duro-sense.com.

Monday, November 12, 2018

Friday, November 9, 2018

Platinum Resistance Temperature Detectors

Platinum Resistance Thermometers Detectors (RTDs) rely on the fact that platinum, like many other metals, exhibits increased electrical resistance as temperature rises. For example, a conventional RTD designed to provide 100 Ohms at 0 °C has a resistance in the neighborhood of 80 Ohms at -50 °C and 120 Ohms at 50 °C, or a sensitivity of about 0.4 Ohms per degree. RTDs constructed to particularly exacting specifications, termed Standard Platinum Resistance Thermometers, are named as the defining measurement tools for interpolating temperatures under ITS-90. In general, RTDs can have high accuracy (0.01 °C), stability, and repeatability across a wide range of temperatures from -200 °C to 500 °C.

Typically the platinum element is formed into thick or thin films, or the platinum wire is arranged in two, three or four helical coils (see diagram, right) – the more coils, the higher the sensitivity. The film or wire is placed inside a glass or ceramic enclosure, and can be supported by loose or compacted MgO. Platinum-based leads connect the probe unit to the thermometer electronics, which convert the electrical signal to temperature.

RTDs are broadly divided into two groups: Industrial RTDs and Standard Platinum Resistance Thermometers, depending on sensitivity and robustness. ASTM and IEC define several classes of RTDs, each with a different set of specifications. An ASTM "Class A" unit, for example, has an out-of-the-box tolerance — maximum permissible error — that ranges from 0.47 °C at -200 °C to 0.13 °C at 0 °C to 0.98 °C at 500 °C.

Advantages

Disadvantages

Typically the platinum element is formed into thick or thin films, or the platinum wire is arranged in two, three or four helical coils (see diagram, right) – the more coils, the higher the sensitivity. The film or wire is placed inside a glass or ceramic enclosure, and can be supported by loose or compacted MgO. Platinum-based leads connect the probe unit to the thermometer electronics, which convert the electrical signal to temperature.

RTDs are broadly divided into two groups: Industrial RTDs and Standard Platinum Resistance Thermometers, depending on sensitivity and robustness. ASTM and IEC define several classes of RTDs, each with a different set of specifications. An ASTM "Class A" unit, for example, has an out-of-the-box tolerance — maximum permissible error — that ranges from 0.47 °C at -200 °C to 0.13 °C at 0 °C to 0.98 °C at 500 °C.

Advantages

- Wide temperature range

- Resistance-temperature relationship is well characterized.

- Rugged construction in industrial RTDs

- Available in different shapes and sizes – application specific

- Can be used with a digital temperature read-out device.

Disadvantages

- Mechanical shock and vibration will cause drift.

- Deterioration at elevated temperatures (e.g., >500 °C)

- 2-and 3-wire devices need lead-wire compensation.

- Non-hermetically sealed RTDs will deteriorate in environments with excessive moisture.

Post abstracted from "Mercury Thermometer Alternatives: Platinum Resistance Thermometers (PRTs)" by NIST.

Subscribe to:

Posts (Atom)